Why JITbase

Workforce efficiency vs. KPI tracking

Collecting live data from machines is considered a key milestone in the Industry 4.0 journey, yet Machine Monitoring Systems suffer from a bad reputation:

X Limited to no payback

X Nice-to-have tool that does not bring improvement (“I know my machines are inactive 70% of the time, I don’t need to pay a system to tell me”)

X Perceived by operators as systems to track employees

Based on these observations, JITbase worked in collaboration with leading manufacturing companies in the precision machining sector to develop a system that uses machine data to improve production planning and scheduling and better manage human resources on the shopfloor.

Although we use machine data, JITbase is not a traditional Machine Monitoring System that tracks OEE, but is a Scheduling & Workforce Management System.

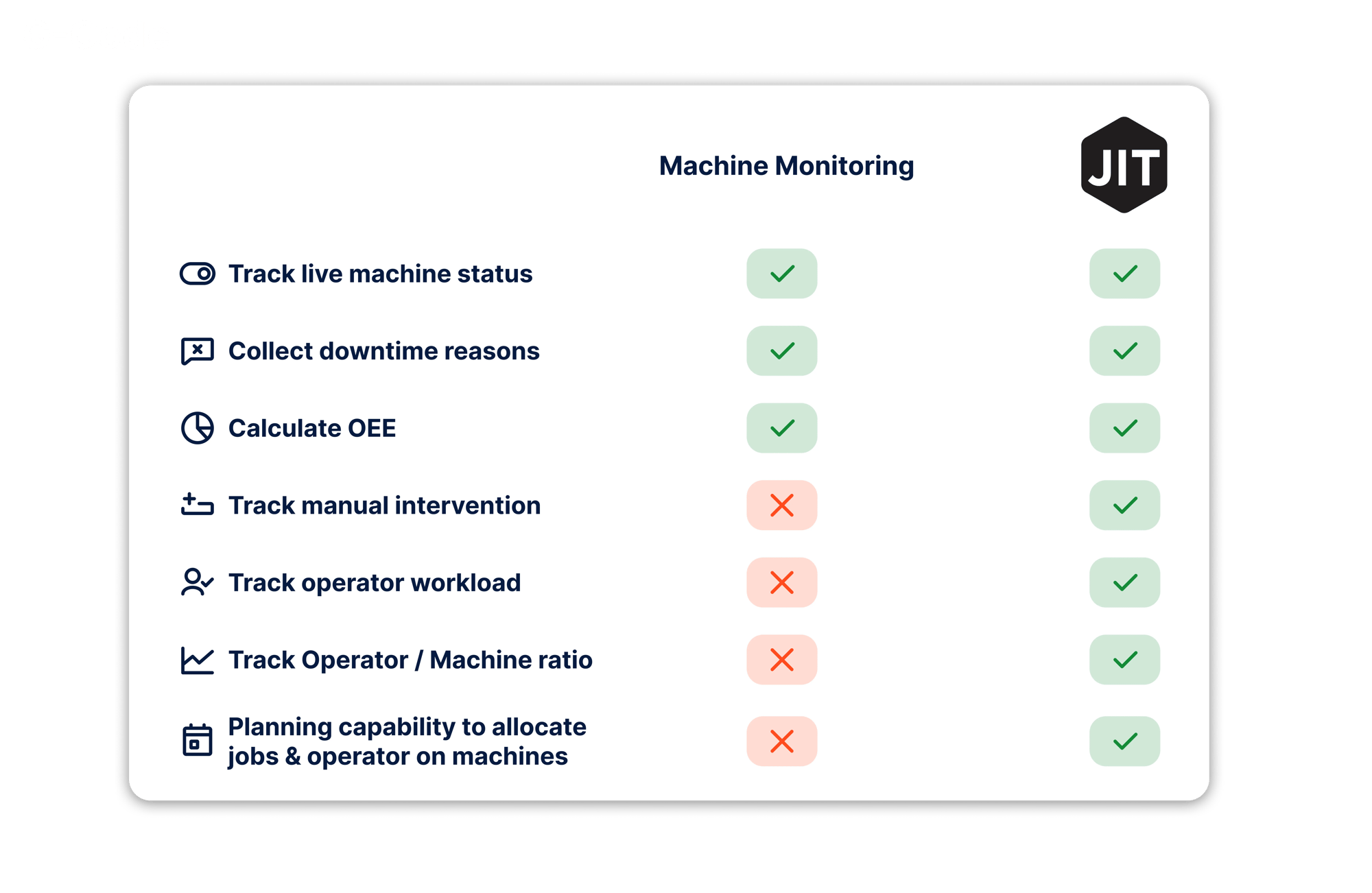

Features that traditional Machine

Monitoring System can’t provide

Based on years of R&D, JITbase transforms machine data into data about the workforce and CNC programs that no one else has.

This new layer of information unlocks new capabilities:

Track Tool path, changeover & M00 standard times

Improve costing and planning

Improve CNC programs

Improve job & operator allocation

Track Operator Workload

Live guidance for Operators

Live job advancement

Go beyond machine monitoring with

features only JITbase provides:

Get accurate standard times by CNC program

Get accurate standard times by CNC program

- Better costing in ERP system

- Better planning in ERP system

- Improve CNC programs by tracking performance

Simulate and track operator workload

Simulate and track operator workload

- Better daily allocation of operators to machines

- Find what combinations of programs/jobs a single operator can run

Provide live guidance to operators and supervisors

Provide live guidance to operators and supervisors

- Operators can manage more machines

- Supervisors track live progress and performance to adapt and respond more quickly

Software only solution

JITbase was designed to make the implementation process seamless. No hardware is required on modern machines. Simply create your environment from our self-serve interface, follow the instructions to install our gateway on your machine network and add your machine IP addresses to start collecting data.

Easy

Everything can be set up by yourself from our self-serve environment. If you need help, we are a click away to support you.

Quick

It takes less than one hour to create your environment, install the gateway on your network and start collecting data from your first machines

Cost effective

Because the gateway is installed on your own servers and not a piece of hardware, it does not add extra cost and it is easily maintainable by your IT team.

Secured

We know your data is highly confidential. Working with manufacturers in the defense industry, security is a priority. Everything we develop is designed based on the latest security norms.

Like 95% of Fortune 500 companies, we have selected Microsoft Azure as our cloud provider. Thanks to this partnership, we benefit from all the Microsoft Azure security features as well as one of the most - if not the most - reliable and secure cloud hosting services in the world.

Some of the main benefits of our infrastructure:

- Banking-level security with https encryption

- Daily data backups

- Up-to-date — no more expensive and painful upgrades every five years. You always have the latest, most secure version.

- Read-only — JITbase can not interfere with your current system

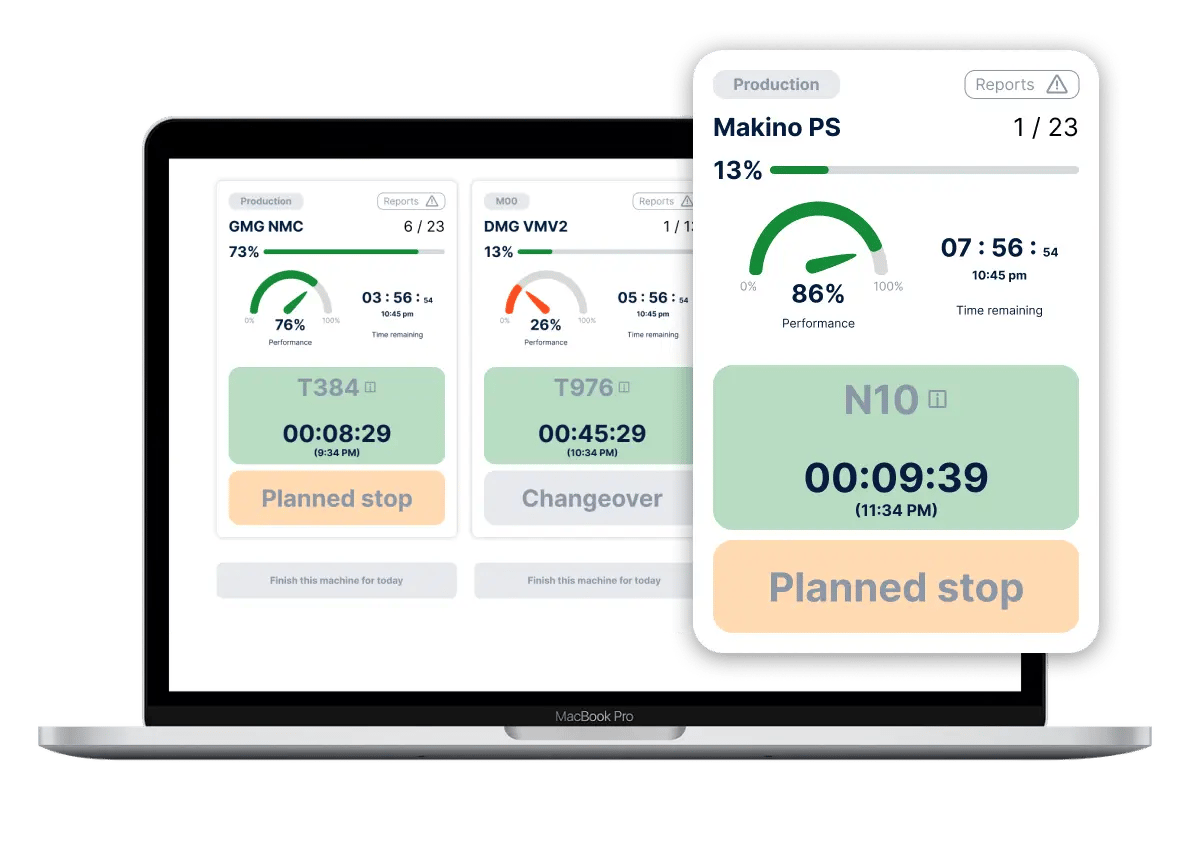

Modern and easy-to-use

JITbase is a modern web application developed by top software engineers with the latest technologies. While manufacturing software often looks old and not user friendly, our interfaces are beautiful, well-designed and self explanatory.

The web application is responsive, which means you can open it on any device (TV, laptop, tablet or smartphone) and anywhere, as long as you have an internet connection.

Ready to revolutionize the way you

use machine data?

Start exploring our solutions now

monitoring

- Live machine status

- Automatically track machine KPI

- Collect downtime reasons

+5-10%

MACHINE UPTIME

monitoring

- Get accurate standard times

- Improve costing and planning

- Automatically track performance

- Improve CNC programs

+10-15%

MACHINE UPTIME

management

- Improve production scheduling

- Improve Operator allocation

- Track operator workload

- Live guidance for operators