POWERED BY MACHINE DATA

PRODUCTION PLANNING & WORKFORCE MANAGEMENT

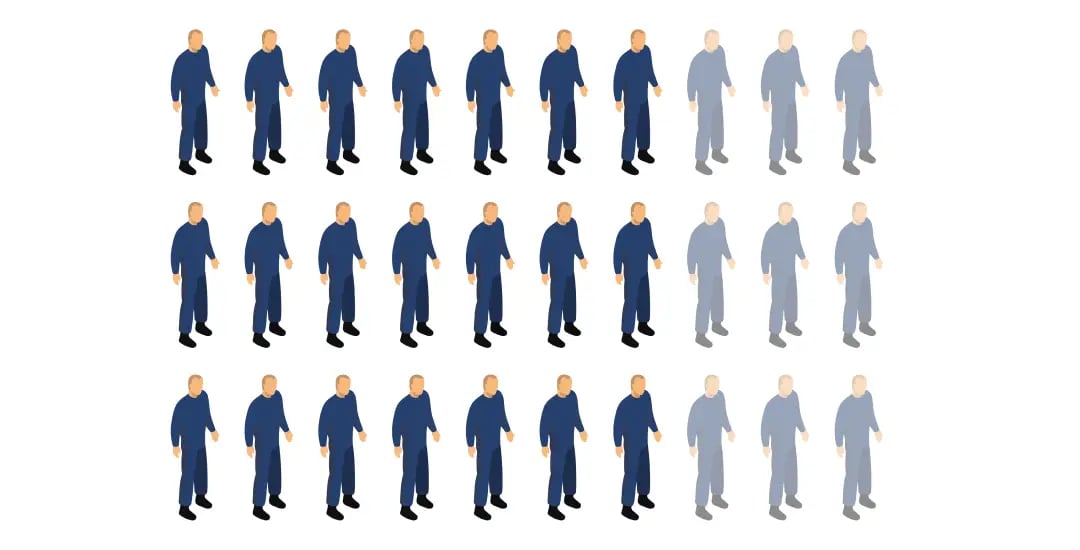

The new bottleneck? Lack of human resources.

Existing manufacturing software like ERPs, MES, APS, or Machine Monitoring systems may tell you about your machines, but they leave humans out of the equation.

JITbase's Production Planning and Workforce Management system fills this gap by collecting data on the workforce that no one else has.

Increase your workforce by 25%...

...without hiring new operators

We maximize machinists’ production efficiency

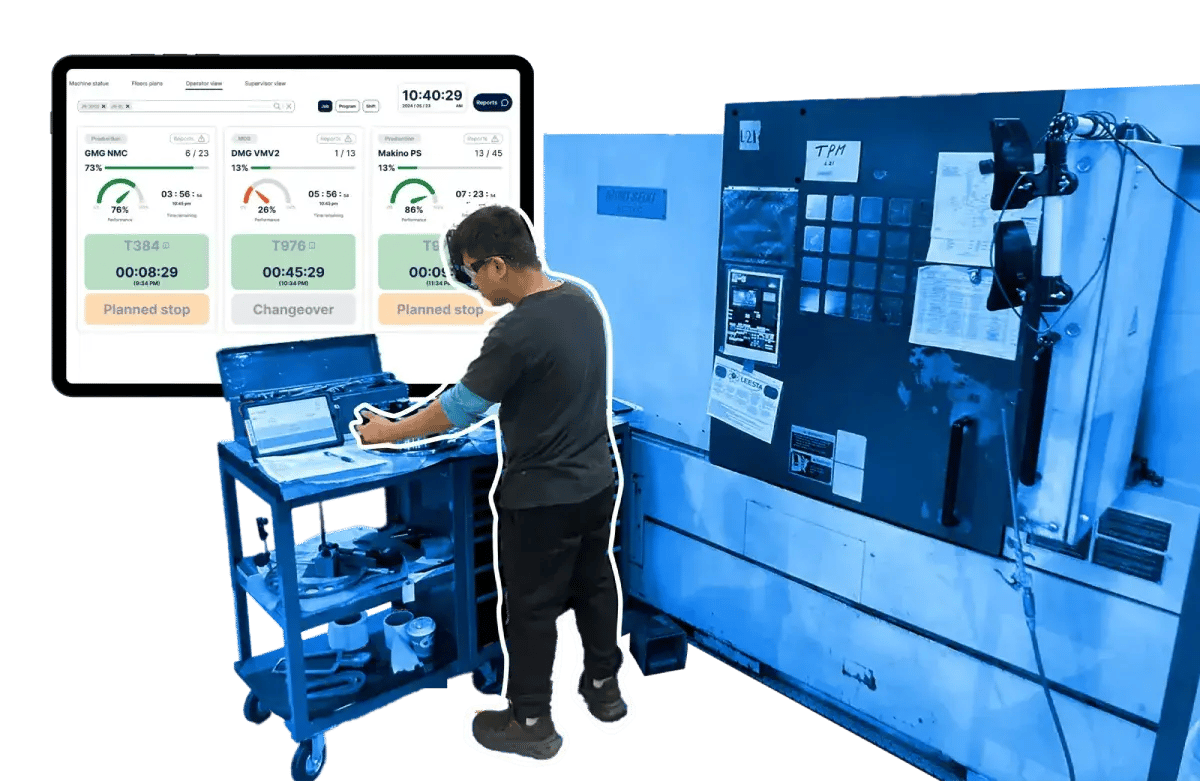

JITbase is the first CNC machine monitoring software to use machine data in order to improve production planning and workforce efficiency

Download the case study"Current machine-monitoring systems show you how bad your production is. JITbase also provides the right tools to improve it.”

President of Leesta

Ernest Staub

The labor shortage impacts your production capacity…but you have no data on:

- How many manual interventions are there in each shift?

- How long should they take?

- How long do they actually take?

- Are my operators efficient?

- What is their workload?

- Can they manage more machines?

JITbase gets data that no one has

Powered by machine data, JITbase automatically learns from CNC programs to get accurate cycle times for all machining and manual operations in addition to machine uptime tracking. JITbase provides a deep understanding of the machining process and manual interventions, providing just-in-time (jit) machining data to your operators and supervisors.

Get accurate standard times by CNC program

Get accurate standard times by CNC program

- Better costing in ERP system

- Better planning in ERP system

- Improve CNC programs by tracking performance

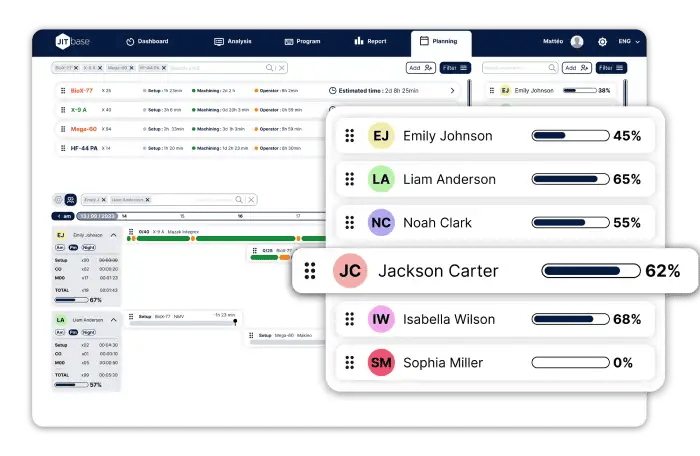

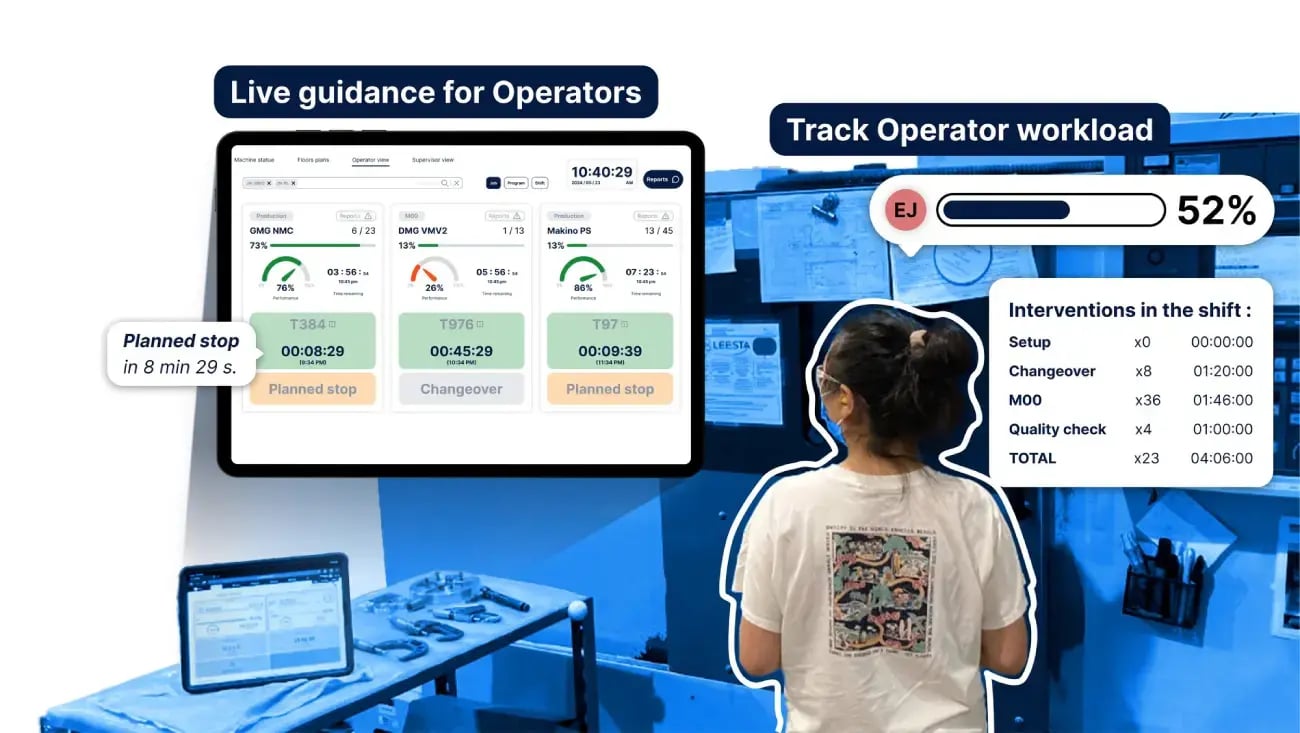

Simulate and track operator workload

Simulate and track operator workload

- Better daily allocation of operators to machines

- Find what combinations of programs/jobs a single operator can run

Provide live guidance to operators and supervisors

Provide live guidance to operators and supervisors

- Operators can manage more machines

- Supervisors track live progress and performance to adapt and respond more quickly

+25%

of Workforce Efficiency =

of Production Capacity

Reduce lead time, reduce hiring needs, improve margins, unlock opportunities for new contracts

Monitoring

- Automatic CNC machine data collection

- OEE software

- Live CNC machine status

- Automatic CNC tracking and machine KPI

- CNC machine analytics

- Collect downtime reasons

+5-10%

MACHINE UPTIME

Monitoring

- Get accurate standard times

- Improve costing and planning

- Automatically track performance

- Improve CNC programs

+10-15%

MACHINE UPTIME

management

- Advanced production planning

- Improve production scheduling

- Improve Operator allocation

- Track operator workload

- Live guidance for operators

+15-25%

MACHINE UPTIME

Let’s get started

Try JITbase's free CNC machine monitoring software (up to 5 CNC machines)

Solve the labor shortage by making your workforce more efficient.