PRODUCTION MONITORING

Automatically collect standard times of your CNC machine programs.

Use this data to update information in your ERP and MRP systems for better production cost analysis and for better production planning.

Track the performance rate of your CNC programs and detect opportunities for improvement.

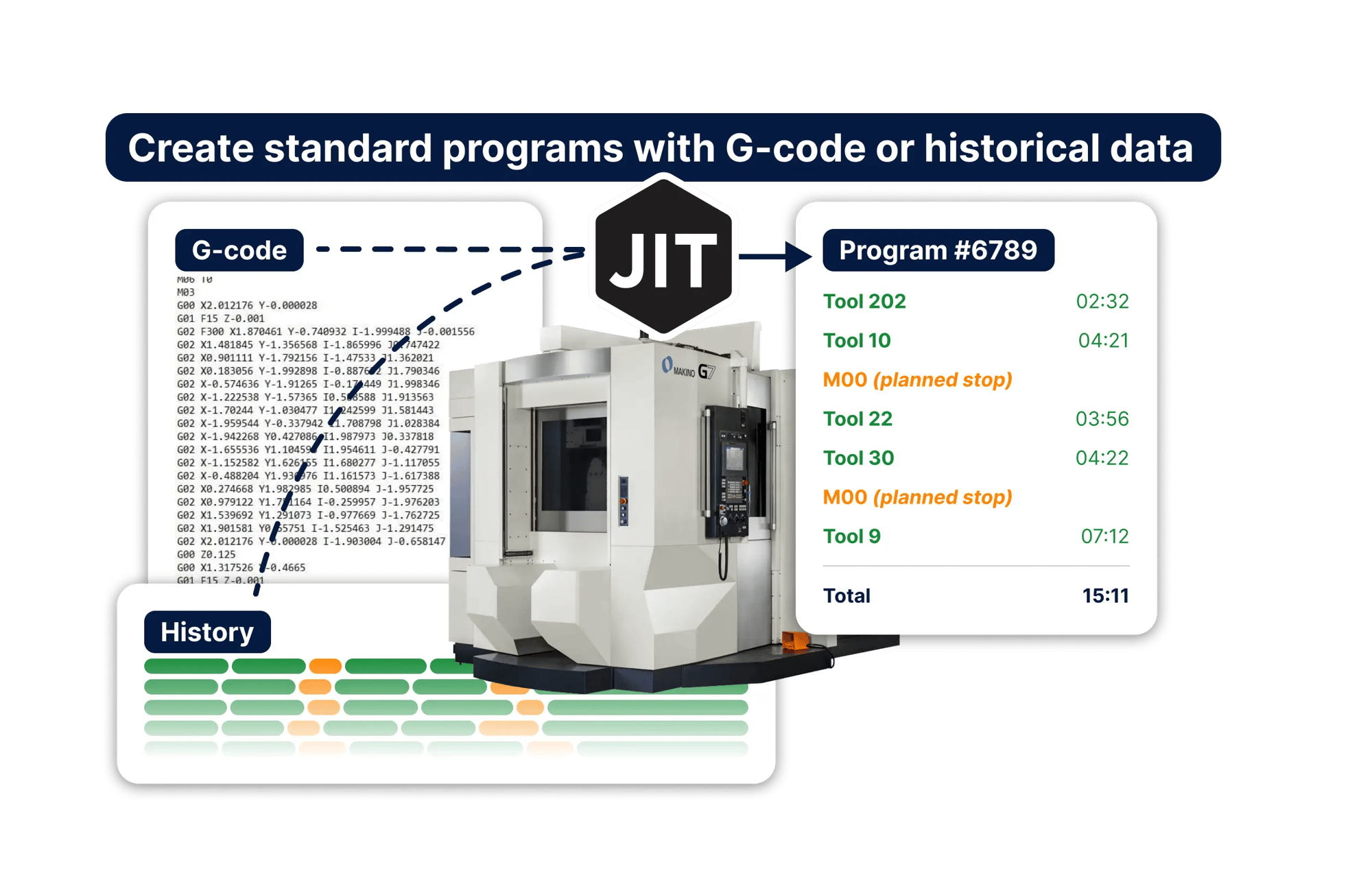

Accurate Standard Times

JITbase real-time monitoring system acquires accurate standard times of your CNC programs either by looking at the G-Code, or using historical data after a few runs collected by our CNC machine monitoring software.

Based on real production data, JITbase also collects setup times, part changeover times, and planned stops (M00 CNC code) performed by the operators, allowing you to have a complete picture of the machining process to manufacture a part.

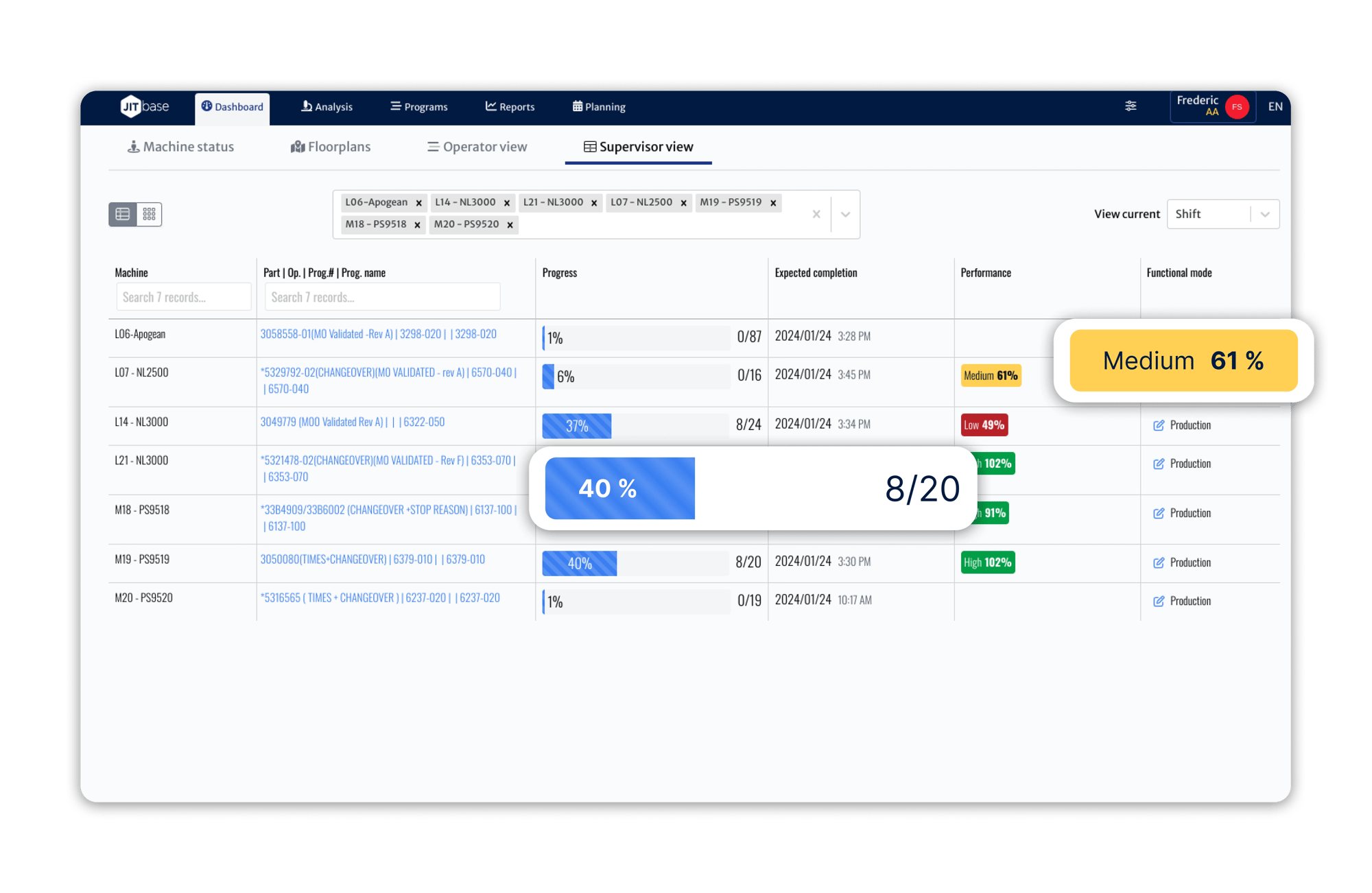

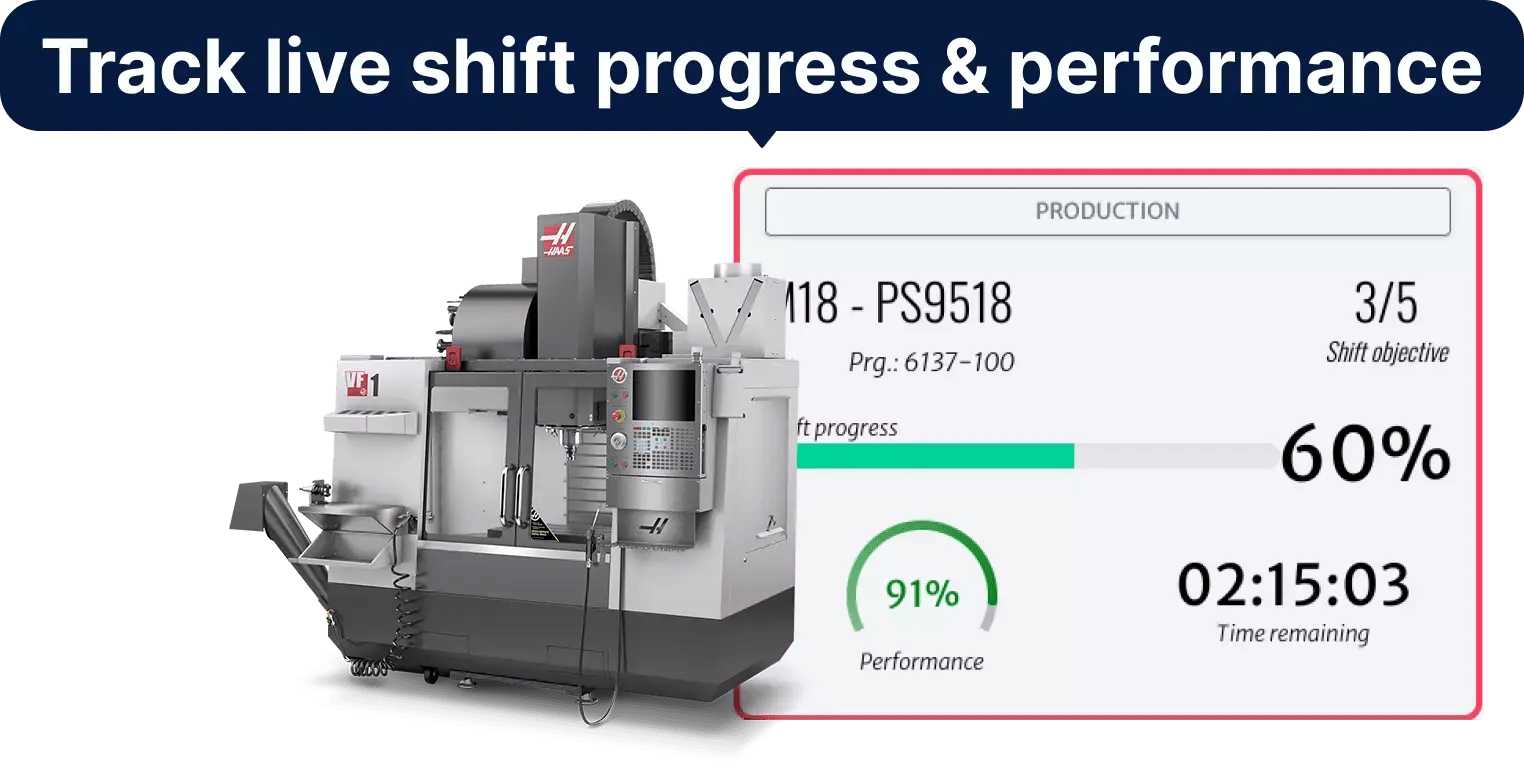

Shift Performance & Shift Advancement

JITbase automatically collects standard CNC times of setups, machining cycles, M00 and part changeovers using our CNC monitoring software.

Instead of tracking machine utilization or OEE, track valuable metrics in production such as Shift Performance by machine and live Shift Progress.

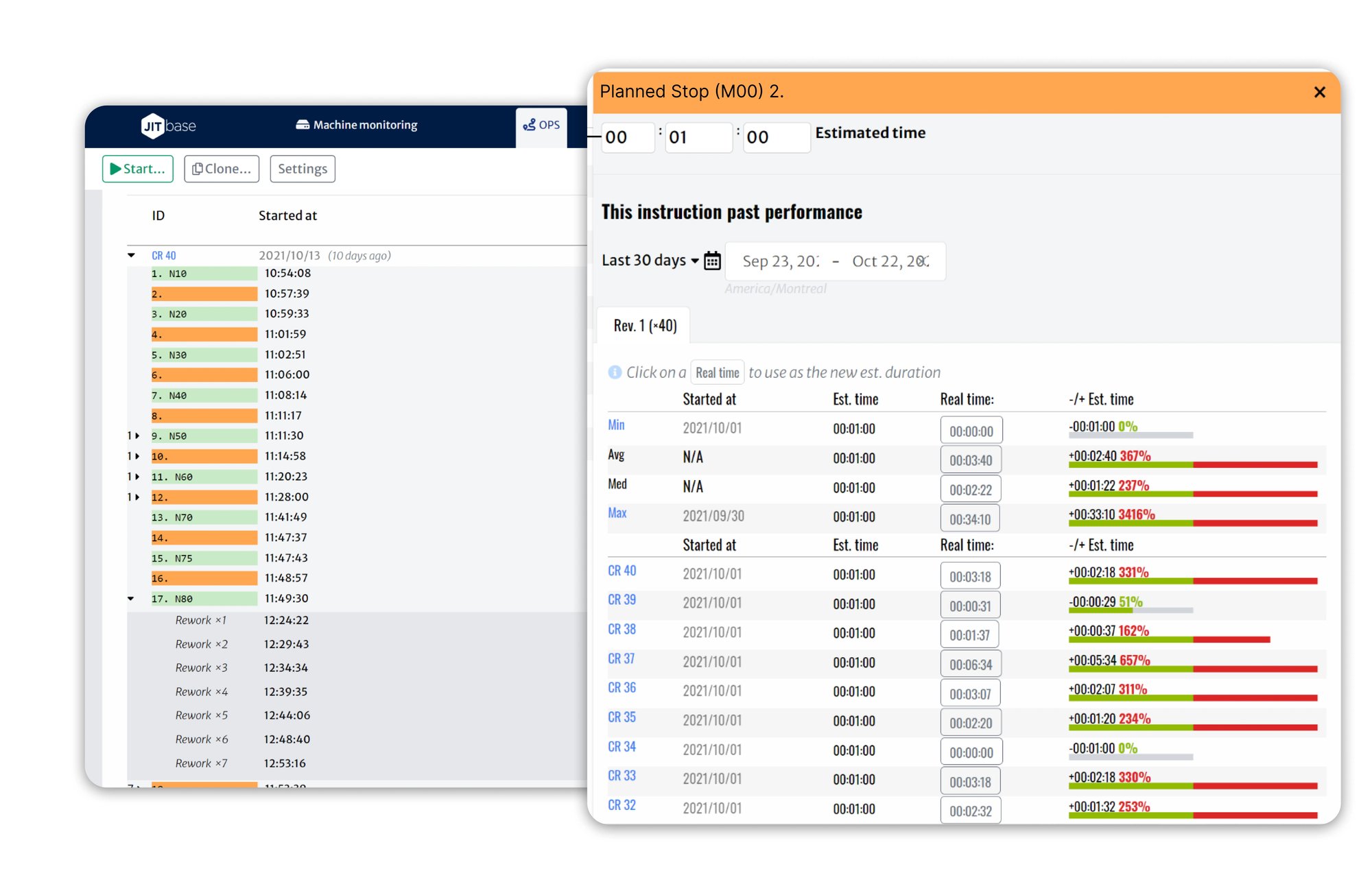

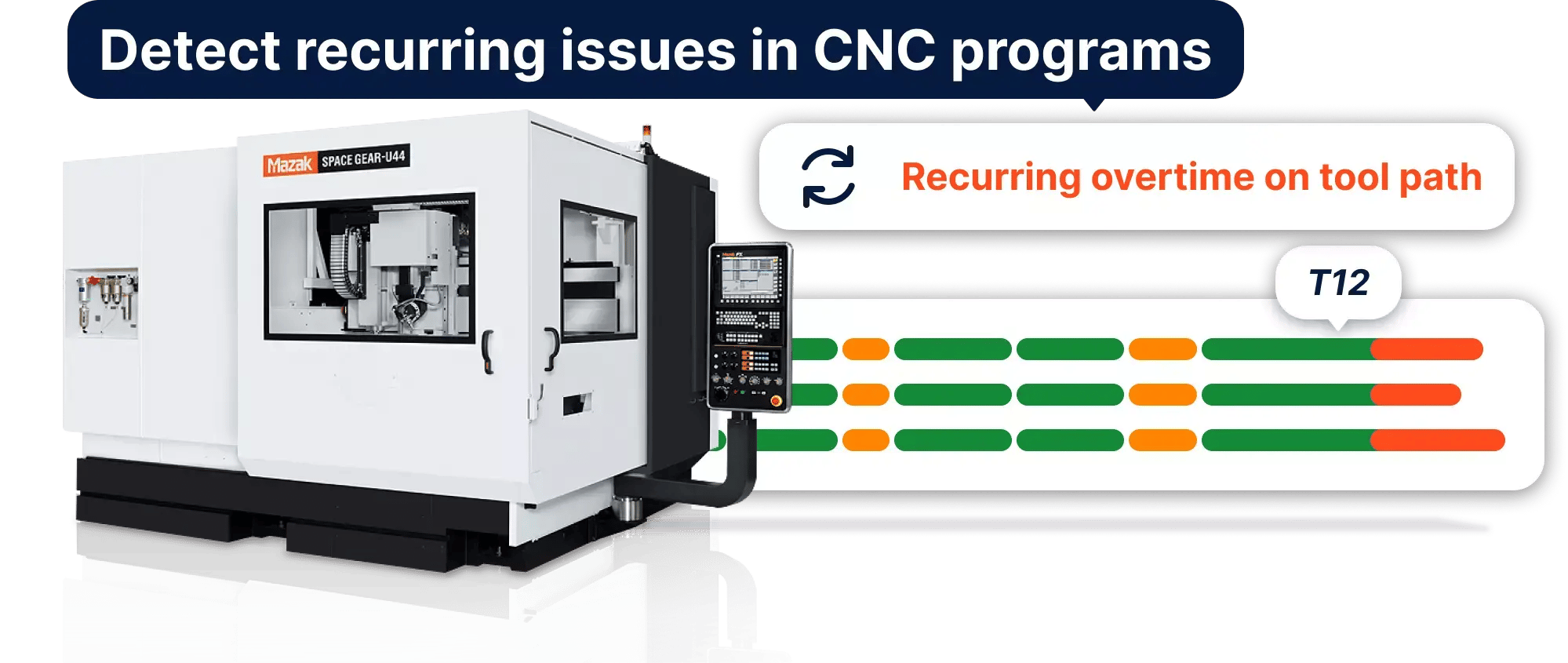

Tool path & M00 CNC tracking

Using CNC tracking, JITbase automatically collects cycle times at the tool path level to detect overtime or use the information with your tool life monitoring software.

JITbase also tracks planned stops (M00), which helps to understand standard times on manual tasks to properly run a program.

This can detect unnecessary planned stops that are not performed in production (only a few seconds long) so you can remove them.

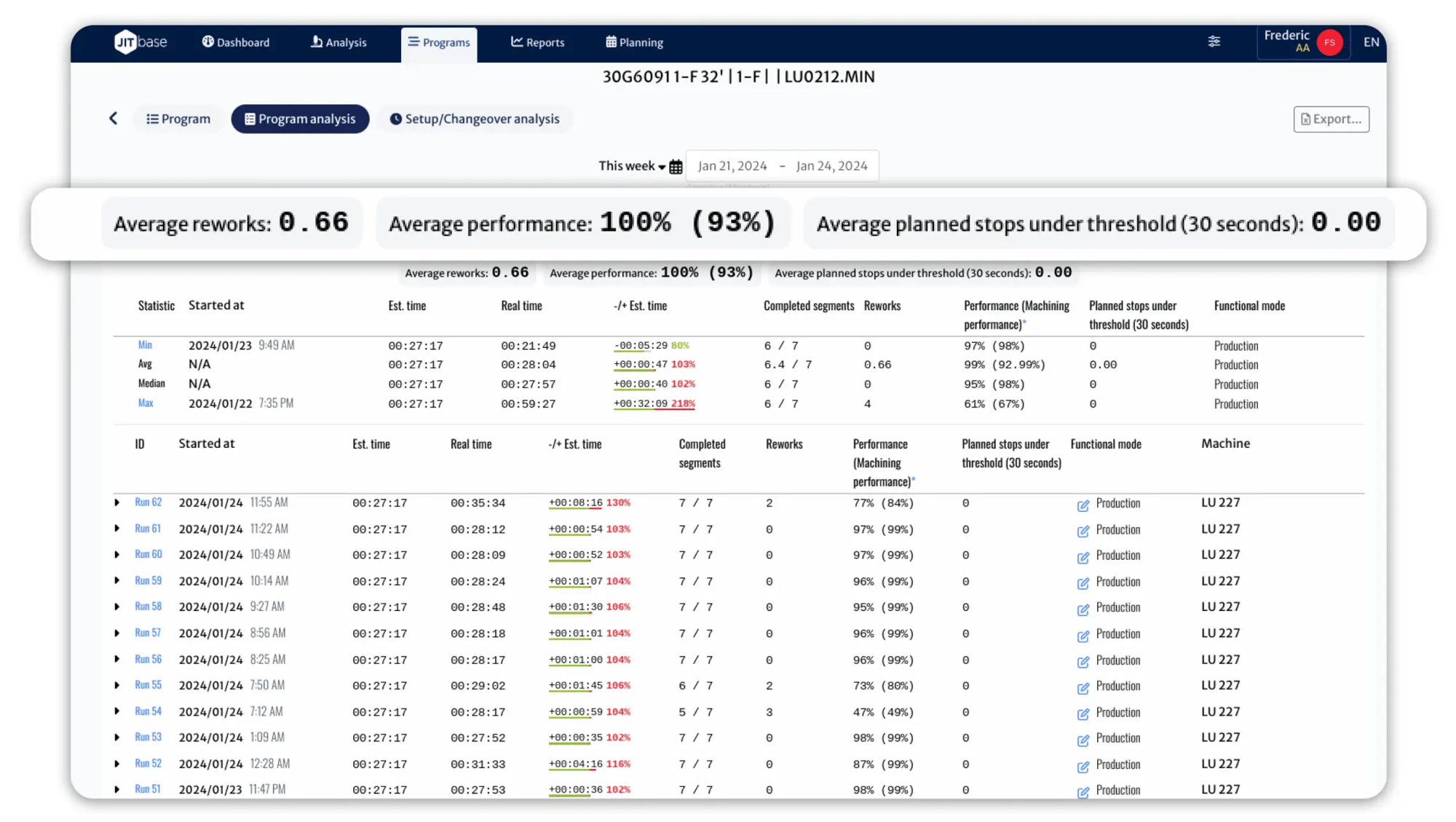

Live Performance tracking

The CNC Machine Performance rate is a much more insightful key performance indicator than CNC Machine Utilization rate, which is usually tracked by Machine Monitoring Systems.

By comparing the actual time of any operation (machining or manual) with the standard time, JITbase automatically tracks:

- Job performance; Work Order performance

- Program performance

- Shift performance

- Setup performance

- M00 CNC code performance

- Part changeover performance

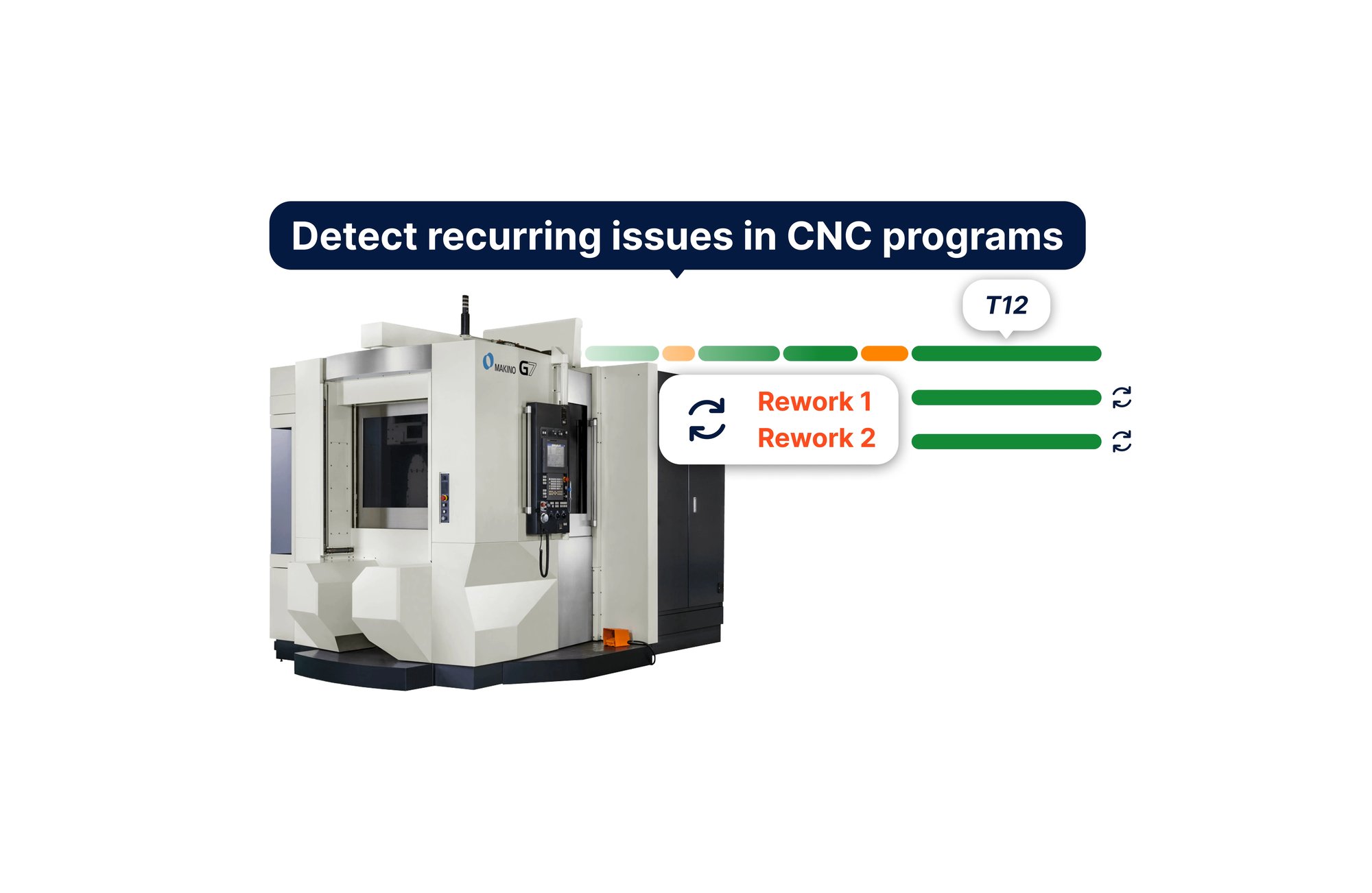

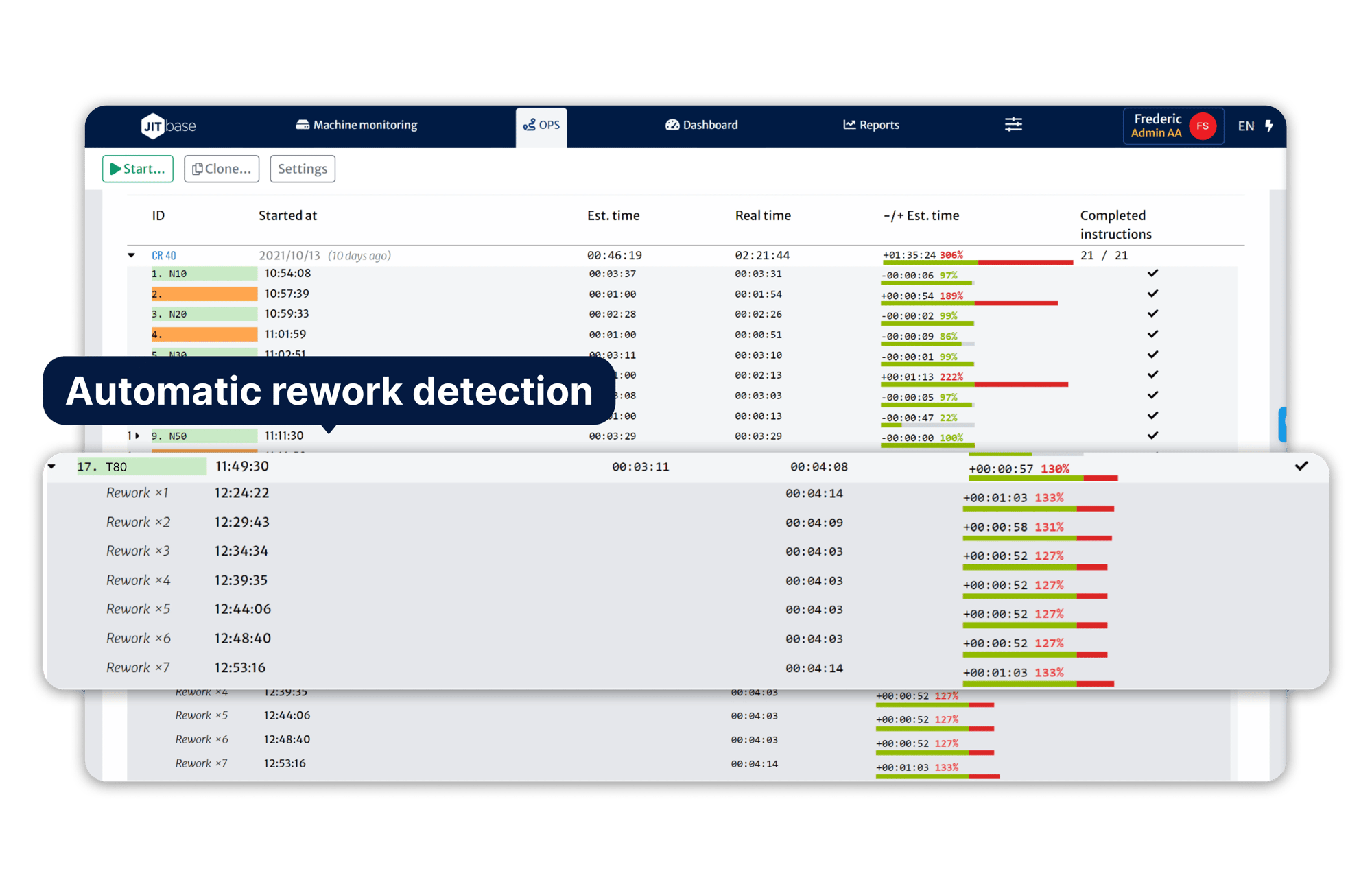

CNC Program Improvement

Program analysis helps understand and resolve recurring problems in CNC programs with low performance.

Examples of recurring problems detected by JITbase:

- A specific tool path that takes longer than expected

- Recurring unplanned stops in the same section of the program

- Use of Optional stops (M01)

- Activation of a feed or speed override

- Tool paths re-run by the operator (also called reworks or unplanned spring passes)

By precisely identifying recurring issues, Methods Engineering can better find solutions to remove them.

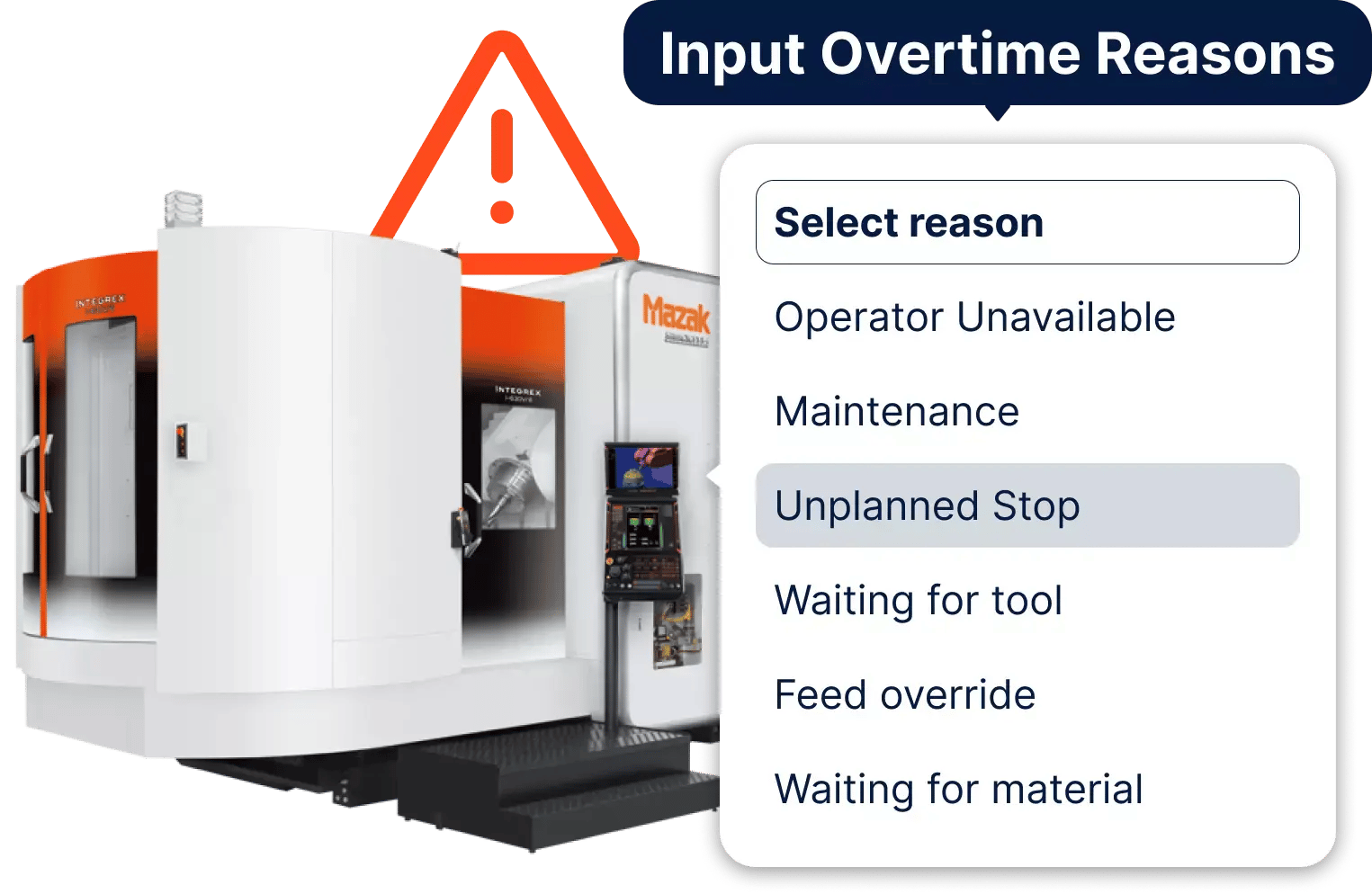

Track CNC Machine Overtime reasons instead of Downtime reasons

While conventional CNC Machine Monitoring Systems ask Operators to input downtime reasons, JITbase automatically knows whether the machine is in setup, part changeover, planned stop or unplanned stop.

In JITbase, Operators can input overtime reasons when the operation takes longer than the standard (plus a defined threshold).

For example, if a setup takes 90 minutes instead of 60 minutes, the Operator can input a reason for the additional 30 minutes in JITbase, while in conventional Machine Monitoring Systems, the Operator would enter 'Setup' as a downtime reason.

Lights-Out Operations

CNC Program Monitoring helps identify productions that can be automated. That is why top manufacturers use it to drive their automation strategy.

JITbase CNC Program Monitoring helps detect:

- Reliable CNC programs with limited to no variation in production

- CNC Programs with high machining vs. human intervention ratio

- CNC Programs with unnecessary M00 that can be removed

Ready to track performance and improve your CNC programs?

Book a time with one of our experts or use our self-serve environment to try our free CNC machine monitoring software today.