Key Takeaways:

- JITbase has launched a free, self-serve version of its Machine Monitoring software.

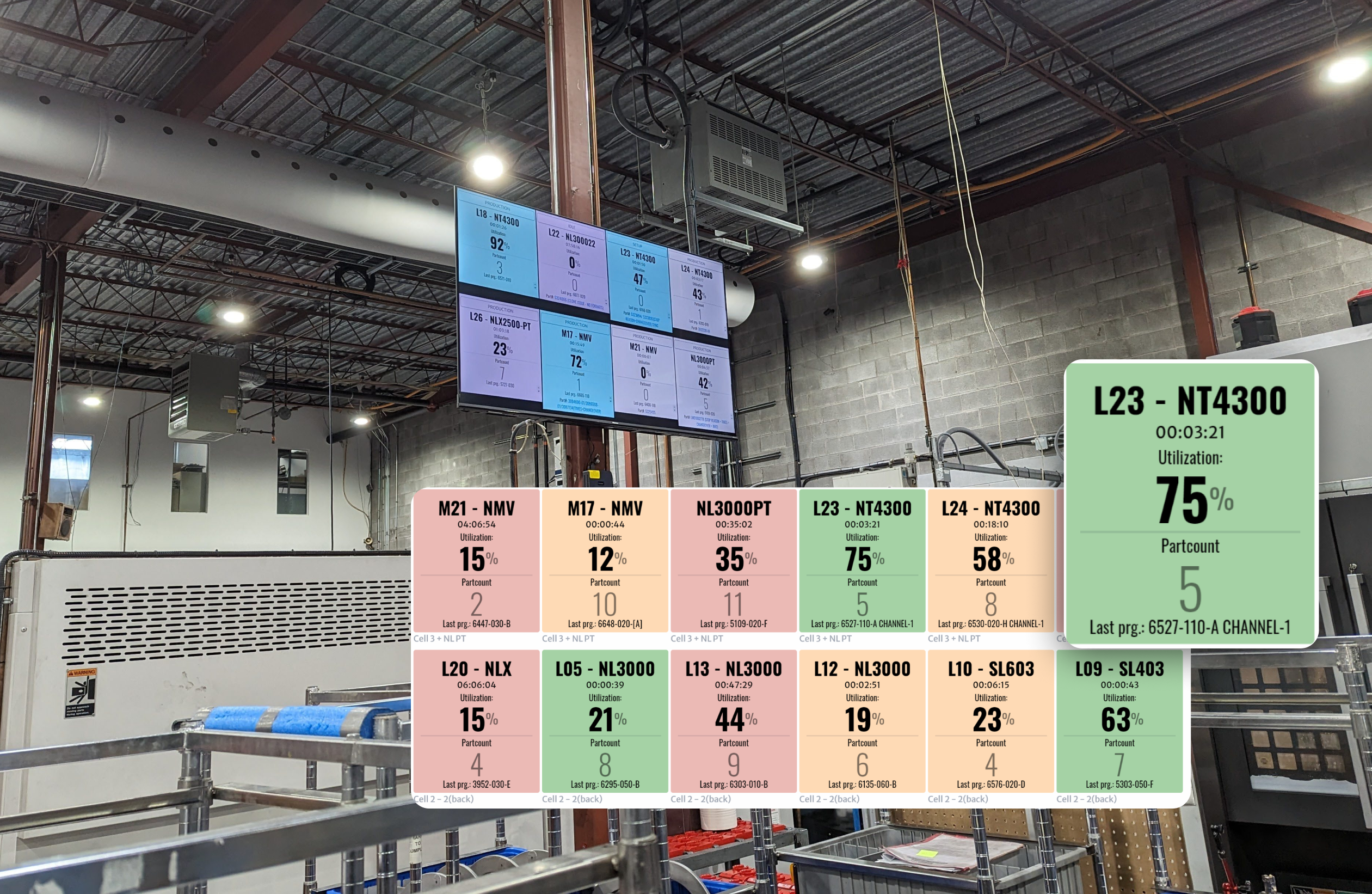

- Key features of machine monitoring: users have access to real-time dashboards, OEE tracking, and downtime reasons, among other essential production monitoring features.

- Easy installation: The software can be quickly set up from our website in self-service, if the machines are already connected to the network with a standard communication protocol (MTConnect, FOCAS, etc.).

Is it Really Free?

It is 100% free for up to 5 machines.

You will have access to all conventional features of machine monitoring

What you get:

Why are you offering it for free?

We believe that acquiring real-time machine data and monitoring OEE are fundamental necessities for any modern manufacturing company today.

While our competitors in the Machine Monitoring and MES space only provide these basic features, JITbase goes beyond traditional OEE and downtime tracking by using machine data for live planning, production scheduling and labor management.

While our unique value proposition will help you reach new levels of productivity and workforce efficiency with a tangible payback, Machine Monitoring will only help you to understand your current level of productivity.

For these reasons, we are pleased to launch and give you access to the first free machine monitoring software on the market!

Consult our white papers and case studies to see how we’ve helped existing customers eliminate waste, overcome the machinist shortage, and improve their OEE:

Is it easy to install?

Try by yourself by creating your account:

1. Install the JITbase Gateway on your CNC Machine Network

- Microsoft Hyper V

- Virtual Box (version 6)

- VMWare

2. Connecting your machines

Good to Know

- Name of the program

- Tool changes

- M00s

- Part counts

- Execution state (active, stopped, interrupted, etc.)