The Ubiquity and Limitations of Excel in Machine Shop Daily Planning

Key Takeaways:

- 99% of machine shop supervisors use Excel to plan and schedule daily production because MRP and MES systems do not provide the flexibility required due to constant emergencies on the shop floor

- Despite its ease of use, cost-effectiveness, and flexibility, Excel has significant limitations due to manual data entry, lack of real-time updates and limited visualization

- By connecting the planning to the machines, JITbase brings a new tool to the supervisors for daily scheduling, with advanced analytics to better manage the workforce and optimize operator allocation

Excel has become a staple in machine shops worldwide, offering a versatile and accessible tool for daily planning and operations. Its widespread use is a testament to its capabilities in handling data, creating schedules, and managing workflows. However, relying exclusively on Excel also brings several limitations that can hinder efficiency and growth. In this blog post, we will explore why 100% of machine shops use Excel for daily planning, discuss its limitations, and suggest solutions to overcome these challenges.

Why Machine Shops Rely on Excel

Planning is an integral part of production; with increasing challenges related to on-time delivery and global supply chain issues, it is crucial to properly schedule production and have a reliable production plan. Without this, a late delivery can cause downstream repercussions that will cost your clients millions and label you as an unreliable supplier.

In order to quickly and efficiently plan work it is easy to see why machine shops overwhelmingly chose spreadsheets:

- Ease of Use: Excel is user-friendly and widely known, making it an easy choice for planning and data management.

- Cost-Effective: As part of the Microsoft Office suite, it is often readily available and doesn't require additional investment in specialized software.

- Flexibility: Excel’s features allow for custom planning templates, data analysis, and reporting tailored to the specific needs of a machine shop.

- Compatibility: It can import and export data from various other systems and formats, ensuring seamless integration with different aspects of operations.

Limitations of Using Excel for Daily Planning

Despite its advantages, relying solely on Excel for daily planning in machine shops has significant drawbacks:

- Manual Data Entry and Errors: Unless you are a programmer or have a dedicated IT team, Excel requires manual input, which is time-consuming and prone to human error. A single mistake can lead to inaccurate planning and costly production repercussions.

- Lack of Real-Time Updates: Excel spreadsheets are static and do not provide real-time data updates. This limitation can result in outdated information, leading to inefficient decision-making.

- Scalability Issues: As a machine shop grows, managing large volumes of data in Excel becomes cumbersome. Excel’s performance can degrade with complex, large datasets.

- Limited Collaboration: While Excel allows for some level of collaboration, it is not ideal for simultaneous multi-user access, which can lead to version control issues and data inconsistencies.

- Inefficiency in Advanced Analytics: Excel has basic analytical tools, but it falls short when it comes to advanced data analytics, predictive maintenance, and optimization algorithms that modern machine shops require.

- Security Risks: Excel files can be easily shared and modified, posing potential security risks and data integrity issues.

- Hard copies never Up-to-date: As soon as you print a hard-copy of your plan, the data is already out of date. Keeping your team informed of the latest changes requires a great effort at a lot of paper.

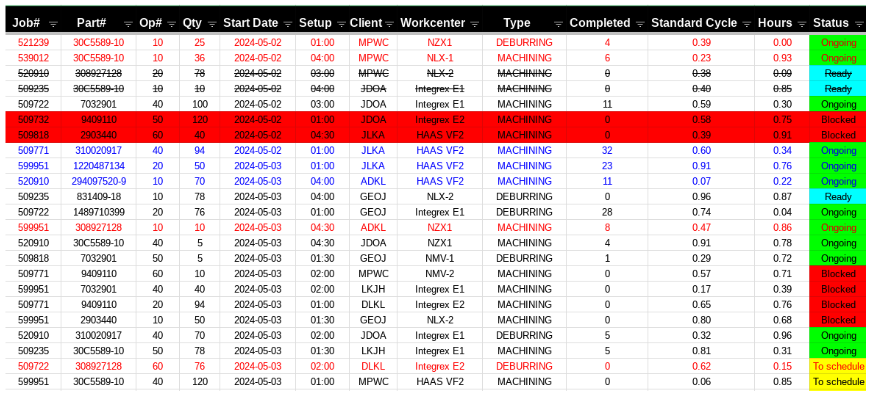

Typical Excel spreadsheets that Supervisors have to maintain

Consequences of Excel’s limitations

- Inefficiency: Too much time is spent planning and re-planning the day’s or the week’s tasks where a manager’s time could be better spent fine-tuning the operations of the machine shop

- Bad Resource Allocation: Without correct, real-time information your production planning may not be assigning the correct machinist to the right machine, or you may be assigning a high-value resource to a machine which can run without supervision for long periods of time, resulting in a loss of productivity from that resource

- Non-Optimal Decisions: While Excel is good at allowing you to fill cells with data, it does not give you any feedback about that data: is this the optimal allocation of resources? Am I going to meet my production deadlines? Is there a bottleneck that the data is not showing me?

Solutions to Overcome Excel’s Limitations Using JITbase

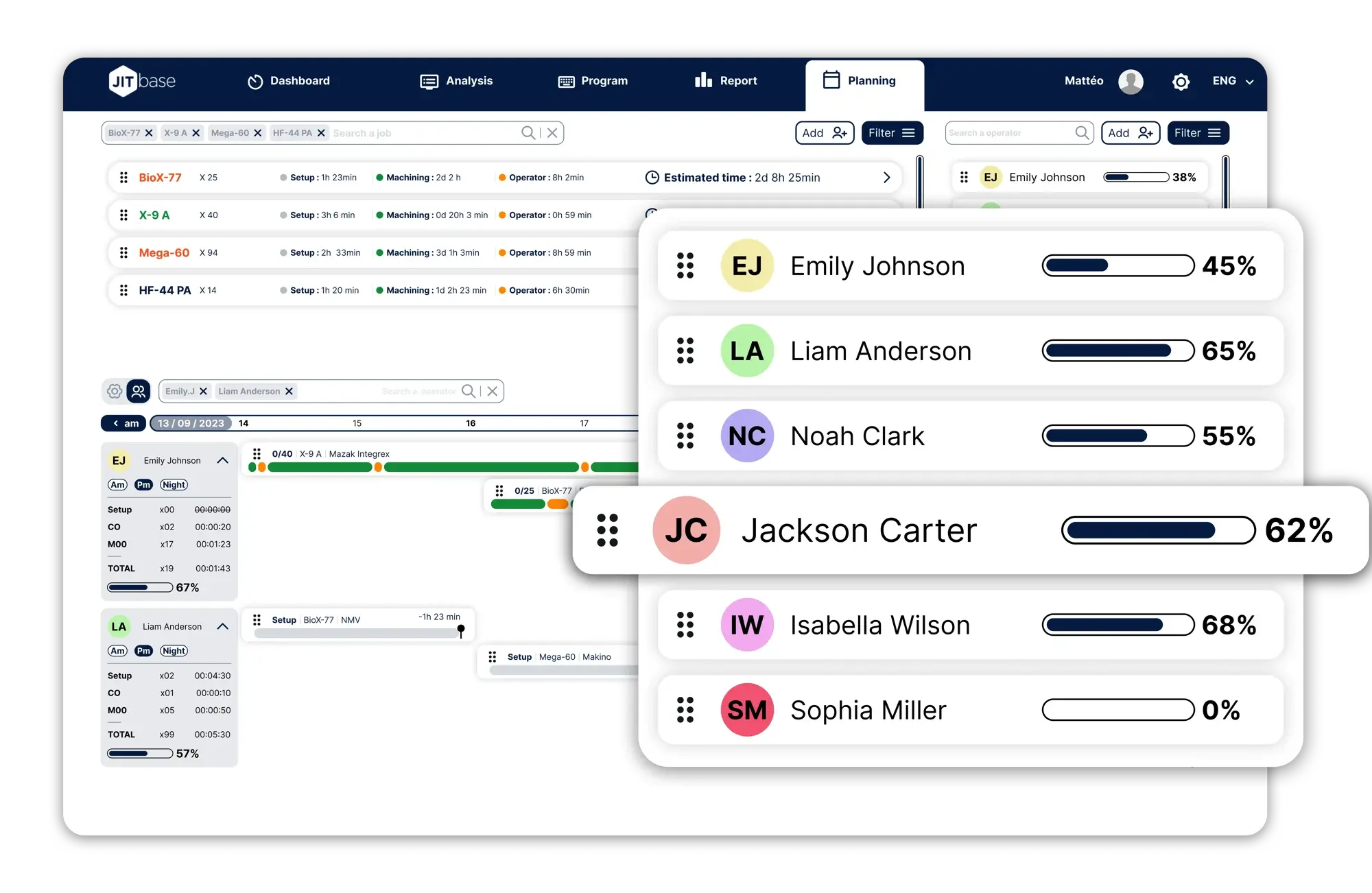

To address these limitations, JITbase has introduced a Planning and Workload Management tool to help supervisors allocate the right amount or resources to the right machine(s) based on accurate workload estimates and real-time data:

- Automation of the planning process: Thanks to live machine data collection, planning is now a dynamic and reactive process with real-time updates to estimated job completion and machinist workload by shift as jobs are prioritized and moved from one machine to another.

- Reduced Errors: Because estimated times are pre-programmed into JITbase or learnt by JITbase based on past productions (including manual tasks) there is less chance to input an error into the planning process. You simply drag-and-drop the jobs to the desired machines and assign machinists who are most available to ensure accurate completion dates

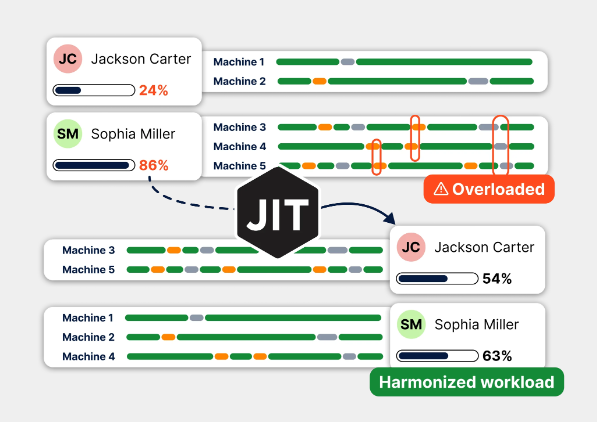

- Optimized Resource Management: Thanks to JITbase’s operator workload calculation feature, you can allocate the right number of machinists to machines. If a job requires very little manual intervention then you can assign the machinist to monitor a 2nd or 3rd machine, optimizing the resource allocation.

Supervisors make better decisions by understanding Operator workloads in the shift

If a job requires a lot of manual interventions, allocate multiple machinists to the job and spread the workload around more equitably.

4. Real-Time Updates: As parts are produced, the JITbase planning tool updates in real-time. You can up to the minute estimated completion times which take company down-time into account (eg. no night shift to continue production from 7pm to 7am for example)

Scheduling and Workload Features

- Scheduling: Advanced algorithms to optimise production planning

- Resource Management: Optimal Operator and Machinist allocation, based on calculation and monitoring of workloads

- Dashboards: Up-to-the-second WO progess and production management visualisation for both the Supervisors and Production Managers.

- Analysis reports: Detailed reports on production performance to help make better decisions

Conclusion

Although Excel is a powerful tool for many tasks, its limitations can hinder the efficiency and growth of machine shops when used for daily production planning.

By integrating JITbase for production and labor management, machine shops can overcome these limitations, improve productivity, and foster continuous improvement. The transition from Excel to JITbase can be very quick by creating an account directly from the website and creating your work orders (WO) in just a few clicks.

The long-term benefits of a production plan connected to your machines, real-time data access, and consideration of all manual interventions by your operators will help you reach new heights in production capacity and on-time delivery.

By integrating JITbase for production and labor management, machine shops can overcome these limitations, improve productivity, and foster continuous improvement. The transition from Excel to JITbase can be very quick by creating an account directly from the website and creating your work orders (WO) in just a few clicks.

The long-term benefits of a production plan connected to your machines, real-time data access, and consideration of all manual interventions by your operators will help you reach new heights in production capacity and on-time delivery.

Try out our Production Planning and Scheduling tool for free: